Equipment

Truck Checks: More transmission tips

Picking up where we left off in the March issue of Fire Fighting in Canada (go to www.firefightingincanada.com and click on past issues), each transmission has a governor.

April 28, 2008

By Don Henry

Picking up where we left off in the March issue of Fire Fighting in Canada (go to www.firefightingincanada.com and click on past issues), each transmission has a governor.

The governor is connected to the transmission output shaft and the

faster the shaft spins the faster the governor turns. This rotation

causes weights in the governor to fly outward because of centrifugal

force, and to open ports in the governor valve body.

It is through these ports that transmission oil flows and causes the transmission to up shift or downshift.

Different governors will have very different shift profiles and must be matched to the valve bodies.

The modulator valve in the transmission is also another input source.

Its position is determined from the throttle pedal in cab.

These two pressures are used to decide when the transmission up shifts or down shifts.

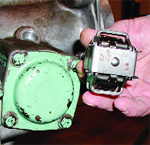

A two- or three-digit number is inked on the head of each governor.

(See photo 2.) This number must match the information in the parts

book. If a shifting complaint is received, it might be because an

incorrect governor has been installed or because the governor is

defective. Either of these problems will cause the transmission to

shift too early (no power) or too late (very harsh shifts).

|

|

| ALLISON TRANSMISSION Model MT 643 serial number 0101818, with an assembly number of 6884350. |

PHOTO 2 Governor valve, number 53. |

|

|

PHOTO 3 An MT 643 four speed with a conical style governor filter. |

PHOTO 4 A typical barrel-type governor filter, located behind the large nut on a MT 653 five-speed Allison transmission. |

|

|

| PHOTO 5 A typical torque converter. |

PHOTO 6 Looking up at a radiator transmission oil cooler assembly. |

The governor is the closest thing this non-computerized transmission has to a brain. Like any mechanical parts, over time, the governor can wear out, causing erratic shifts You may wish to keep one of these units in stock if you have several with the same number.

Inspect the gear on the governor for wear. The governor is powered from the tail shaft and the faster the governor turns, the higher the governor pressure.

This pressure is used to indicate to the shift valves in the valve body when to shift (either up or down).

If this gear were to break at a high road speed it would cause very, very rapid downshifts. After the truck was stopped, you would find that you had only first speed forward or reverse speed and you could never up shift to second gear. Inspect this gear for wear.

The governor valve receives its oil from the main pressure oil gallery. Before the oil can get to the governor valve, it flows through a governor filter. If this filter were to plug up, then the governor could not get the correct oil pressure. This filter is often neglected during service work. There are two different types: a conical type or a barrel type. (See photos 3 and 4.)

The torque converter ratio

(See photo 5.) The proper torque converter ratio is selected after the information on the engine horsepower and torque, the rear axle ratio, the size of the tires, weight of the vehicle, terrain the truck will work in, and the number of transmission gears (four or five speed).

These numbers can be as low as 3.04:1 or as high as 1.82:1. What do these numbers mean? Like any transmission ratio, the number is given as something to one (i.e. 3.04:1). This means that the engine will turn 3.04 times for one turn of the torque converter output shaft. This reduction in speed means an increase in torque. In this case, say the engine could develop 400 foot pounds of torque (1779 N), then the maximum the torque converter could output to the transmission would be 400 foot pounds times 3.04, or 1,216 foot pounds of force (5409 N).

This would only happen if the engine were at full throttle and the truck was just starting to move, such as during a quick acceleration out of the fire hall.

This is called a stall condition and it only happens when the torque converter is at maximum vortex flow. This high vortex flow comes at a price and that price is a development of very high heat generated in the oil flowing inside the torque converter.

This heat is very destructive to the oil and therefore also to the transmission if allowed to continue for long.

Your truck should have a transmission oil temperature gauge. If it did not come with one, get one at the assembly plant and have it professionally installed.

The torque converter ratio is further multiplied by the transmission ratio. For example, in first speed, an MT 643 has a forward ratio of 3.58 to 1 and when multiplied by the torque converter ratio of 3.04 to 1, you have a stump-pulling ratio of 10.88 to 1.

With an MT 653 deep-reduction model, using the same torque converter, it would be possible to produce a very low ratio in first speed of 24.42 to one.

Each torque converter is matched to the truck and any changes to the tire size, rear axle ratio or engine may require a change in torque converter ratios and valve body adjustment, for which you must see your authorized Allison dealer for support.

Warning: Make sure that when you rebuild or replace a transmission you use a torque converter of the same ratio. There are very few identifying marks on the outside of a torque converter and it is very easy to mistake the ratios.

Engine RPM

The engine rpm is very important for several reasons. When a driver accelerates out of the fire hall, the transmission is designed to up shift to the next highest speed, about 250 to 100 rpm below full governor engine rpm (also called no-load governed or high-idle speed by some manufactures), depending on the model.

For example, if the engine were intended to run at a maximum of 2,100 rpm, then at a full throttle up shift on this model, the up shift should happen at 1,750 rpm. (Note that information on throttle up shift is in the service manual; get a copy.)

If the engine could never reach 1,800 rpm, then the transmission would never shift to a higher speed when the throttle pedal was fully depressed.

I have seen this done by well-meaning souls who honestly thought they were going to make the engine last longer if it did not go as fast.

The maximum engine rpm that the transmission is rated for must match the maximum rpm that the engine is rated for. This information is available on the engine and on the pump panel. Not only must these numbers be the same but the engine must be able to actually access this rpm. (See stall test for further info on the relationship between the transmission, torque converter and the engine.)

Modulated lockup

When the transmission is in either second or third speed (depending on the model – again this information is in the service manual) of a four-speed transmission, the torque will lock up and, in effect, go into a one-to-one condition as you travel down the road.

This means that the engine torque and speed will not be changed by the torque converter; this is done to improve engine fuel economy.

But it also has another effect, that of ‘engine braking’ as you come to a stop. With the foot off of the throttle, the truck’s engine will act as a brake to help stop the truck. A good driver can use this to increase the life of the service brakes.

The job of the modulated lockup is to hold the torque converter in this lock-up condition as the truck slows down. In some models, this engine-braking condition can be held almost until you come to a complete stop; in others until about 10 miles a hour. Not all models have this modulated lockup. The assembly number will indicate whether your transmission has a modulated lockup. Please refer to these numbers in the parts manual before you disassemble the transmission to repair a defective modulated lock-up valve on a transmission that does not have one. Really. Trust me.

Now you can see how important these SAM (serial, model and assembly) numbers are. It is almost impossible to do any maintenance, repair or diagnostic work if you do not have this information.

As we have seen, the transmission oil can get very hot. This high heat is destructive to the oil. The normal oil operating temperature is between 160 and 200 F (71 to 93 C). The temperature should never exceed 300 F (149 C). Transmission oil cooler is used to remove this destructive heat from the oil. This cooler used coolant from the radiator to remove this heat. (See photo 6.)

After a transmission is rebuilt, it is not common for the oil-cooler lines to get re-connected incorrectly, but it can happen. This will not cause an overheating problem right away but on the first hot day, on a trip with hard accelerations, the transmission oil will begin to overheat.

If the transmission uses a transmission retarder, then an even larger capacity cooler must be specified when the truck is assembled, as this retarder will use the transmission’s oil to convert the forward speed and energy of the truck into heat, just like the wheel brakes convert the forward motion into heat when they stop the truck.

If this heat is not removed from the oil, the oil will very quickly deteriorate. This oil will have a black or dark colour instead of the normal red colour of Dexron. The oil may also have a burned smell. This overheated oil will develop a sticky varnish coating on the valves in the transmission. This varnish will cause erratic and unpredictable shifts both up and down. If this condition is allowed to continue, then the clutch packs may not get the correct pressure to ensure that they are fully engaged; this will cause the clutch packs to burn as they will slip under engine power. This will release more contamination into the oil and further deteriorate the oil.

If there is one thing I have found that will extend the life of this transmission, it is the maintenance of the transmission oil. At Lakeland College here in Vermilion, Alta., we have 15 trucks with various models of the Allison transmission. Students drive these trucks very hard all spring, summer and fall. These transmissions get their oil and filters changed once a year and they have not had any lubrication or filtration-related problems.

An excellent source of additional information is, of course, the Allison website www.allisontransmission.com There are numerous free PDFs on all Allison transmissions. The operator tips files are prefixed by the letters OM and the mechanics tips are prefixed MT. In my opinion, you should only use genuine Allison parts and filters when servicing your transmissions.

Don Henry teaches in the Automotive Service Technician and Heavy Equipment Technician programs at Lakeland College in Vermilion, Alta., where he has been a faculty member for more than 17 years. He has co-developed and delivers Canada’s only post-secondary level fire-apparatus maintenance program and has completed a textbook on fire apparatus.

Don Henry teaches in the Automotive Service Technician and Heavy Equipment Technician programs at Lakeland College in Vermilion, Alta., where he has been a faculty member for more than 17 years. He has co-developed and delivers Canada’s only post-secondary level fire-apparatus maintenance program and has completed a textbook on fire apparatus.

Print this page