Equipment

Truck Tech: November 2013

The number of firefighters killed while riding to and from calls in apparatuses has dropped over the last five years, as have the number of those who have become physically disabled and unable to return to work because of injuries from collisions.

November 12, 2013

By Chris Dennis

The number of firefighters killed while riding to and from calls in apparatuses has dropped over the last five years, as have the number of those who have become physically disabled and unable to return to work because of injuries from collisions. This decrease is largely due to the safety features now found in fire trucks.

■ Seatbelts

Today’s custom-built apparatuses are manufactured to NFPA standards and have a plethora of safety features suggested by experts in the Canadian fire service. The one thing the trucks can’t do is make firefighters abide by the rules.

|

|

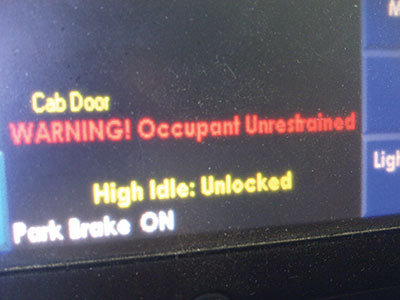

| Photo 1: The safety system in modern fire trucks will not only detect when a passenger is not wearing a seatbelt, but will also recognize when the belt has been cheated, for example, if the belt is buckled up before the occupant is seated. |

|

|

|

| Photo 2: Neglecting to wear a seatbelt will trigger a red light on the dash or on the multi-plex screen indicating that an occupant is not buckled up.

|

|

|

|

| Photo 3: The system can also determine where the unrestrained passenger is seated, making it easy for the officer to determine who is not wearing a seatbelt. Advertisement

|

|

|

|

| Photo 4: Each tire on the truck must have a visual indicator or monitoring system to show when the air pressure is low. photos by Chris Dennis |

In Ontario, the Ministry of Labour’s Section 21 advisory committee on firefighter occupational health and safety recommends that firefighters stay seated when in the truck and wear their seatbelts.

There is an exemption under the Highway Traffic Act for firefighters occupying the seat behind the driver’s cab “where the performance of work activities make it impracticable to wear a seat belt assembly.” But the Section 21 Committee recommends that seatbelts always be worn while the vehicle is in motion.

The seatbelt is a certified, engineered and well-tested piece of safety equipment. Seatbelt placement and design in fire trucks is unique because of SCBA and bulky PPE. While three-point harnesses are the most common type of seatbelt for fire trucks, lap belts can still be found; under NFPA 1901, which applies to all apparatuses ordered on or after Jan. 1, 2009, the lap portion of a seatbelt must be a minimum of 1.5 metres (60 inches) long to fit over bunker gear.

In addition, seatbelt webbing for apparatuses is brightly coloured so that it can be identified as a seatbelt and not be mistaken for a strap for breathing apparatus. Also, in the event of collision, the brightly coloured seatbelt can be easily distinguished from SCBA webbing if it needs to be cut off.

Another important fire-truck safety feature is the sensor that sounds an audible alarm and lights up an icon when the seat is occupied and the seatbelt is not secured. The system will also recognize when the belt has been cheated, for example, if the belt is buckled up before the occupant is seated, as in photo 1. This will trigger a red light on the dash or on the multi-plex screen indicating that the occupant is not buckled up (see photos 2 and 3). Depending on how the system is specified for the vehicle, a data recorder or little black box records the events in the order with which they are completed.

Changes to the NFPA seatbelt standard include a minimum lengthof 1.5 metres (60 inches) for a two-point belt and 2.8 metres (110 inches) for a three-point harness. The longer lengths will help to eliminate complaints that the belts are too short to be comfortably fastened while wearing full turnout gear. A seatbelt extension is not permitted or accepted.

Seatbelts also are now designed such that, in the event of a roll-over, a firing mechanism will discharge and will wind the buckle end of a seat toward the floor, pulling the occupant into the seat. However, this happens only in response to the body-control module’s programming, Buckle up, buckle up, buckle up! If not for your own safety, then for the safety of your brother or sister sitting with you.

■ Tire pressure

Tire-pressure indicators (see photo 4) come in many different makes and models. This is one of two systems that we at Vaughan Fire & Rescue Services in Ontario use. Each tire must have a visual indicator or monitoring system to show when the air pressure is low.

A simplified tire-pressure indicator can be a valve stem cap with a red/green indicator built into the end. Green indicates good pressure and red indicates low pressure. However, I suggest you still manually check tire pressures with a pressure gauge, as per your department’s SOGs. Low tire pressure increases the chance of early tire failure, impacts the tire’s longevity, decreases fuel economy, makes steering stiffer and increases the possibility of rolling tire failures.

■ Data recording

It was not all that long ago that a tachograph was found in fire trucks. The tachograph senses and records road speed, starting and stopping, sudden braking and emergency lights or sirens when activated.

Today, the vehicle data recorder or little black box, much like those found in an aircraft, can be used as a driver training tool. This device keeps a second-by-second record of the vehicle’s speed, acceleration and deceleration, engine speed, throttle position, antilock braking system events, master warning light switch position, date and time, and other conditions on a running 48-hour timeline. It also keeps a minute-by-minute summary of this data on a running 100-hour timeline.

The primary purpose of this vehicle data recorder is to provide accurate evidence of the operating conditions of the vehicle in case of an accident. Departments should set up a formal operating procedure to take vehicles out of service immediately after an accident and have a qualified third party download the information from the vehicle data recorder. Don’t let your shops do it, and don’t alter or erase the information – this can be considered tampering with evidence in a court of law.

■ Reflective surfaces

Fifty per cent of the rear-facing vertical surface of all fire trucks must now be covered with reflective red and yellow, green or orange stripes in a chevron pattern sloping downward from the centre of the vehicle at a 45-degree angle. The stripes must be 15 centimetres (six inches) wide, but can be 10 centimetres wide (four inches) in conjunction with the side graphics.

Although there is some variance on the exact shade of yellow, green or orange that can be used, other colours may not be substituted. Be sure you use NFPA ULC compliant colours and patterns.

■ Stability control

Trucks and trailers have been equipped with roll stability control (RSC), including crash testing and roll-over collisions, for more than 10 years. However, only recently has the RSC been offered on fire trucks. The system is simple but requires certain accessories to make it all come together. I will speak now to Spartan Emergency Vehicle’s system.

RSC is designed to reduce the risk of rollover by electronically slowing the vehicle down during unsafe turns or quick lane changes. It will apply transmission-retarding ABS brakes and take throttle control away from the driver. A turn as simple as one through an intersection or on a ramp with too much list to one side will disable the accelerator pedal so even if the driver is pushing the pedal there will be no response until the onboard computer for this function can determine that it is safe to continue acceleration.

Electronic stability control (ESC) detects skidding and will help to improve the truck’s stability by automatically apply or decelerating the engine’s drive function by way of the gas pedal. It will also engage or disengage the brakes until the driver is able to steer clear and safe.

The safety restraint system (SRS) continually monitors vehicle acceleration and angle in conjunction with RCS and ESC. It will electronically detect the potential for rollover and will apply components as necessary.

For more technical information on the RCS, the ESC and the SRS, perform a basic web search. There is a lot of information out there.

■ Airbags

Side-curtain airbags are now available in many shapes and sizes, depending on the fire truck builder and the system being used. When activated, a large cushion-like bag inflates between the occupant and the outboard position or the doors in 0.234 seconds.

When you are building your next piece of apparatus, inquire about these safety items, because you are your own first line of defence.

Be safe, be protected and, as always, rubber side down.

Chris Dennis is the chief mechanical officer for Vaughan Fire & Rescue Services in Ontario. He can be reached at Chris.Dennis@vaughan.ca.

Print this page