Equipment

Truck Checks: September 2009

Lubrication of transfer cases and fire pumps is crucial. The Waterous transfer case uses an oil splash system and a supplementary pump that draws oil from a sump strainer and sprays it on the chain drive. As this transfer case uses a chain drive, automatic transmission fluid (ATF) is the strainer lubricant of choice for this manufacturer

September 14, 2009

By Don Henry

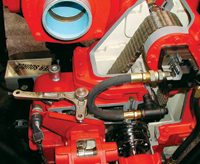

To maximize the life of your equipment, it’s important to understand proper lubrication. Lubrication of transfer cases and fire pumps is crucial. The Waterous transfer case uses an oil splash system and a supplementary pump that draws oil from a sump strainer and sprays it on the chain drive. As this transfer case uses a chain drive, automatic transmission fluid (ATF) is the strainer lubricant of choice for this manufacturer – the same oil that you use in your Allison automatic transmission will work just fine here. The oil should appear just upx to the level of the drain plug. Your transfer case may be equipped with an oil level sight window.

The oil should appear red in colour, not black, and should not have a strong odour indicating that the oil has been overheated. It is, unfortunately, very common to find water in the transfer case oil. This water will, as I have pointed out before in other articles, drastically shorten the service life of your transfer case. It is neither normal nor acceptable for the drained oil to look like Pepto-Bismol. (I use Pepto-Bismol as an example because I am sure almost all fire chiefs are acquainted with this colour!)

|

|

| Photo 1. Waterous pump cutaway – note chain drive. Photos by Don Henry |

|

|

|

| Photo 2. Note oil level window. |

|

|

|

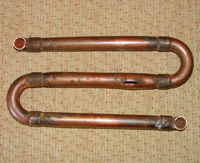

| Photo 3. Cracked transfer case oil cooler. |

|

|

|

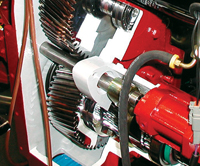

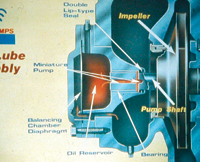

| Photo 4. Typical gear drive transfer case cutaway. |

|

|

|

| Photo 5. Hale auto lube system. |

|

|

|

| Photo 6. Primer oil tank. |

Any water will turn the oil a milky pink colour. How could this water get into a transfer case? In my experience there are three ways. The first is from the normal heating and cooling of the transfer case oil. This cooling draws in small amounts of moisture from the air in the fire hall and contaminates the transfer case oil. This process may take years, but then again it may take years to put on 100 pump hours. The second major cause is poorly adjusted pump shaft packing. The drip rate from just one packing is between a low of eight drops to as much as 120 drops per minute depending on the manufacturer of the fire pump. If it looks like the flow from a garden hose under your fire truck then you can bet that some of this excess water will find its way into your transfer case. It should be noted that there must be some water dripping from the pump shaft – too tight an adjustment will starve the shaft from the needed cooling and lubrication of the pump shaft. It’s not hard to properly adjust a pump shaft seal but it is easy to do it wrong. The third cause is from broken transfer case oil cooler. The cooler in photo 3 was broken because of water that froze in the copper oil cooler at the bottom of the transfer case. This would have been discovered if anyone had got on a creeper during a daily inspection as oil and water was flowing out of the top of the transfer case breather.

If the strainer becomes plugged because of water or other debris make sure you remove this strainer screen and clean it. Waterous recommends this after 100 hours of pumping use or twice a year. A magnetic drain plug is on the bottom of the transfer case; clean it at every oil change. The pump impeller shaft is supported by two bearings; they turn at very high speeds – in many cases nearly twice engine speed. These bearings need to be lubricated with high-speed, medium-thickness ball bearing grease, not the low-speed, thick grease you have been using on steering kingpins, ball joints and fifth wheels. I suggest a lithium-based grease and a NLGI grade of No. 1 or No. 2, no thicker. Don’t over grease. The biggest killer of greaseable bearings is not under greasing but over greasing. Over greasing causes the grease in the bearings to overheat. The grease lubricant will separate from the thicker and leak out leaving just the thicker. The bearing will then seize. In many cases this destruction of the bearing will be mistaken for lack of greasing and the operator will just grease it more often, creating a vicious circle. Waterous recommends three shots of grease for every 100 hours of pumping time. Make sure the grease zerks and grease gun are clean. If in doubt about the grease gun, pump a shot or two into a rag to make sure clean, fresh grease is available. When you are done, leave a small amount of grease on the zerks. This will ensure no water will rust the zerks. Let me stress this again – the grease zerks must be very clean before you pump grease in; if not, any dirt on the zerks will be pumped into the bearings, tremendously shortening the service life of the bearings.

Two other popular manufacturers of high-quality transfer cases are Hale and Darley. Their transfer cases use gears, not the chain drive that Waterous uses and, as such, an SAE EP 90 gear oil, a 10w-40 motor oil or, in some cases, a straight grade 30 motor oil is specified for these units. You will have to check with the manufacturer for the correct grade information and amount. As an example, Darley recommends that the transfer case oil be changed after 20 hours of pumping or every three months.

The Hale fire pump has a very interesting system of lubrication for its pump shaft. As I have said earlier, the pump shafts are supported on roller bearings and, as such, need to be greased. The Hale auto lube is different – while the rear pump shaft bearing is supported by a roller bearing the front of the pump shaft is supported by this auto lube system.

The oil reservoir is filled with oil – often, an SAE EP 90 weight gear oil is used. Water-pump pressure is allowed into the balancing chamber with a diaphragm used to separate the oil and water. As the pump shaft turns, oil is drawn up the centre of the shaft and then, because of centrifugal action, flung out to lubricate the bushing. As the water pressure in the fire pump increases, the amount of oil pressure will also increase because of the balancing diaphragm. This has the effect of maintaining the oil pressure in the auto lubrication system the same as the water pressure in the fire pump, ensuring a long seal life.

Like all things mechanical, pumps do fail. If the pump shaft seal fails then the oil in the chamber will be milky white rather than the amber colour of normal pure motor oil. If the balancing chamber diaphragm fails then water will be flowing out of the oil plug in the upper left-hand corner (see photo 5). In any case, the pump must be repaired. If not, the pump shaft bushing will fail and the pump will require a very expensive and avoidable repair. If you have never checked this oil level, do it today. It is very easy – simply remove the oil plug, insert a clean plastic drinking straw and remove. Make sure the oil level is correct as this system works on the principle that you cannot compress a liquid. The oil chamber needs to be at the correct level for the system to perform correctly.

There are lots of older fire apparatus that use an oil-type primer-vane pump to create the vacuum needed to prime the main fire pump during operations such as drafting. There have been a number of lubricants used over the years to facilitate this. Straight motor oil was common, then multi-grade oil, and, finally, you may have been encouraged to use biodegradable oil such as a corn or rapeseed product. One item you may not have noticed is the elbow brass fitting in the upper left-hand corner (see photo 6). This elbow has a very small hole drilled in it. Do not cover up this hole; it needs to be there. As the primer turns, a small amount of oil is drawn out of this tank and down to the primer vane pump. This oil is used to seal and lubricate the vanes in primer pump. When the primer pump is turned off, this small hole breaks the siphon. If this hole is covered then the siphon effect will drain the tank of all its oil. Then, in the future, the primer vane pump will be starved of oil and not function correctly. Newer fire apparatus may not have a primer tank as the industry has gone to oilless primer systems.

In conclusion, find your trouble light, get on your creeper and start taking lubrication seriously. Change the oil in the transfer cases and take regular oil samples for analysis.

Don Henry teaches in the Automotive Services Technician and Heavy Equipment Technician programs at Lakeland College in Vermilion, Alta. He can be reached at don.henry@lakelandcollege.ca

Print this page