Equipment

Truck Checks: May 2010

Water tanks are a very important component of the fire truck and are often overlooked and under maintained. Water tanks are usually made of steel or plastic.

April 26, 2010

By Don Henry

Water tanks are a very important component of the fire truck and are often overlooked and under maintained. Water tanks are usually made of steel or plastic. The plastic tanks are more correctly called UPF Poly-Tanks and have been very popular for the last 10 to 12 years. Because the manufacturers are very confidant of the UPF tanks they offer a lifetime warranty.

|

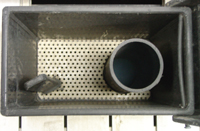

| Photo 1. Looking down on fill hole for a plastic tank; note the removable screen and overflow pipe.

|

|

| Photo 2. Inside view of a steel tank baffle. There’s some corrosion but note the excellent condition of the welds. |

|

| Photo 3. Replaceable anodes mounted in pump piping. |

|

| Photo 4. Note the sacrificial metal in the pump intake. |

|

| Photo 5. Note the leather belting used as a cushion between the tank and the frame. |

|

| Photo 6. Tank to pump line; note the bolts on the right side and the rubber cushion between the frame support and the water tank.

|

|

| Photo 7. A typical water tank level sensor on top of the water tank. Photos by Don Henry Advertisement

|

To a large degree, plastic tanks have reduced many of the corrosion problems associated with steel tanks. They are generally considered to be 50 per cent lighter than steel tanks of the same capacity. The use of this material has allowed for some very interesting options for fire departments, such as the ability to store the ladders lower down on the fire truck with a through-the-water-tank design.

According to NFPA 1901, a pumper must have a water tank of at least 300 gallons (1,100 litres). It is important that the tank overflow direct the overflow water to dump behind the rear axle so this water will not interfere with wheel traction. (See photos 1 and 2.)

Inspect the inside of your steel tank for corrosion. Pay particular attention to the baffles inside the tanks. The baffles perform an important safety function. As the vehicle de-accelerates or turns a corner, the water will tend to stay in motion and force the truck to remain in the same direction. This could cause the truck to flip over. The baffles in the tank, to a degree, stop the water from sloshing in the tank. If the steel baffles have corroded in the tank or have become disconnected from the water tank’s inner walls, the vehicle will become unstable during turns or on corners. A half-full water tank can be dangerous even with working baffles. Many departments have a SOP stating that the fire truck will be driven only with a full water tank or a completely empty water tank. After a fire call, the truck’s water tank is drained if it cannot be filled from a water source, such as a hydrant, before returning to the hall. If you have to use an open water source such as a pond or a roadside ditch, completely flush out the water tank, fire pump and piping after returning to the hall.

When waiting for a call, fire pumps should be kept full of water or empty. Never leave the pump partially full of water. The mix of oxygen and water will cause rust. Most departments keep the fire pump full of water. Departments in northern areas may decide to keep the pump dry to avoid freezing. There will be some corrosion even in water that is of a neutral PH; as the water becomes more basic or acidic, depending on your water source, the rate of corrosion will increase. To combat this problem corrosion, anodes are installed. These anodes are made of a sacrificial metal. (See photos 3 and 4.) As such, over time, the anode will dissolve in the water rather than the more expensive and more difficult to replace pump parts. These anodes can be made like the ones in the picture above or as part of the screens that cover the intake ports to the pump. Most people think that the screen used in the intake ports of a fire pump is there to keep debris from entering the fire pump. It’s really intended to be used by departments that keep their fire pumps flooded with water when in the fire hall. The screen is really a piece of sacrificial metal that is meant to dissolve and, in the process, fight corrosion. How often these will need to changed depends on the condition of your water. Those of you who have attended our fire school in Vermilion, Alta., will understand the problem! In the past, when steel tanks were very common, the water tank, piping and fire pump would experience the effects of this corrosion. Now that we have plastic tanks this corrosion can only occur in the fire pump and piping. In other words, a plastic tank can accelerate corrosion in a fire pump. The anodes and the protection they bring are now even more important as there is less material over which to spread this corrosion.

■ Water tank to frame

The water tank needs to be secured to the truck frame (see photo 5). This is often done with clamps or bolts. There will be a cushioning material between the water tank and frame. On older trucks this was often a strip of hardwood. On more modern trucks a strip of leather belting was often used. Presently, a strip of rubber is most often the material of choice. In any case, these materials will deteriorate over time. I would recommend that these devices be inspected yearly. (See photo 6.)

■ Water tank level sensors

These devices have come a long way from a glass tube on the side of the water tank to indicate levels. (See photo 7.) An excellent website for information on the topic of water level sensors and their maintenance is the MC products web page – www.mcproducts.com/servicemanuals.html. These water level sensors give very little trouble. If the tank level sensors get coated in oil then they may need to be cleaned. The bulbs on the panel are easy to replace and available from almost any auto-parts store. Like most electrical defect problems, these tank level sensors can be broken down into three categories: Opens circuits, such as a break in the wire, are almost always at an electrical connection, unless you have managed to get the wire close to a hot exhaust pipe; A short circuit, also know as copper to copper, will often cause another circuit to be energized; and a ground circuit, often called copper to steel, will almost always melt a fuse or trip a circuit breaker if the problem is on the power side of the load. A high resistance will be caused if the bad ground is after the load. This could cause the light bulbs to be dim instead of bright. Clean the ground connection and protect it from moisture and corrosion. Both short circuits and ground circuit problems can cause a fuse to blow or a circuit breaker to trip. Never replace a blown fuse or circuit breaker with one of a higher amperage rating; it would look bad if the fire truck caught on fire.

■ BOYD COLE EDUCATORS’ MEMORIAL AWARD

Boyd Cole was a pivotal person in the creation of the Apparatus Maintenance Section of the IAFC, The Emergency Vehicle Technician Certification Commission, NFPA 1915 and NFPA 1071 committee, which he chaired, and their standards. He was also very active on other NFPA standards and a long-time member of NFPA 1901 and NFPA 1914. He personally taught fire apparatus aerial courses across the United States and Canada and was instrumental in the formation of a number of state associations as well as being a mentor to many. Boyd was a long-time employee of Underwriters Laboratory. His belief in the need for technician training and certification was absolute. Without the support of educators like Boyd Cole, the level of technician training would not have advanced to where it is today.

In memory of Boyd Cole, the EVMS will be presenting an award each year at Fire Rescue International (FRI) to recognize an educator, trainer, or facilitator of emergency vehicle technicians’ training. The award will be presented at the EVMS two-day pre-conference workshop and will consist of a wall plaque and ticket to the pre-conference workshop. To ensure that the person can attend and accept the award, the EVMS will pay for airfare and two nights’ accommodation in an area hotel. The EVMS will solicit only the State and Provincial EVT Associations for nominations for this award.

The nominee may be a corporate, private or public sector educator, trainer or facilitator of EVT training. The nominee cannot be a currently sitting director of a nominating organization. The deadline for nominations is May 30. Please respond with all relevant documentation supporting your nominee to don.henry@lakelandcollege.ca. A committee has been formed to select the candidate.

Don Henry teaches the Automotive Services Technician and Heavy Equipment Technician programs at Lakeland College in Vermilion, Alta. He can be reached at don.henry@lakelandcollege.ca

Print this page