Equipment

Truck Tech: February 2011

Whether your department is staffed by full-time firefighters, volunteer firefighters, or both, you likely have some small gasoline-powered equipment on your trucks – chainsaws, positive pressure fans, remote generators, portable pumps, heavy hydraulic pumps and quick-cut saws, to name a few (see photo 1).

February 8, 2011

By Chris Dennis

Whether your department is staffed by full-time firefighters, volunteer firefighters, or both, you likely have some small gasoline-powered equipment on your trucks – chainsaws, positive pressure fans, remote generators, portable pumps, heavy hydraulic pumps and quick-cut saws, to name a few (see photo 1).

|

|

| Photo 1: Chainsaws, quick-cut saws, portable pumps, and marine outboards are examples of two-stroke engines. They are categorized as internal combustion engines. Photo by Chris Dennis |

Most of these pieces of equipment have four-stroke or simple two-stroke engines. Both types of engines have benefits and drawbacks, and both styles of engines have a place in the fire service, so there really is no such thing as a bad two-stroke or four-stroke. The application of the engine is what matters. Be sure the right engine is ordered to do the job; if the equipment power is not effective enough, it will not do the job.

■ Two-stroke engines

Chainsaws, quick-cut saws, portable pumps and marine outboards all use two-stroke engines. They are categorized as internal combustion engines.

Gasoline and oil are mixed together to create a fuel mixture that is poured into the gas tank. The mixes are in ratios determined by the manufacturers, so check the owner’s manual for the correct mix of gasoline and oil.

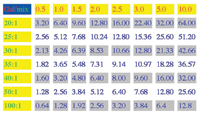

This simple chart at the right may give you a hand in mixing the ratios. It’s a good resource for those who are unsure how to mix.

■ Simple two-stroke pre-mix engines

Positives

- These engines are lightweight.

- Powerful: The spark plug is fired only once on every revolution, giving it twice the power of a four-stroke engine, which fires the spark plug every other revolution.

- No oil sump: You could have a portable water pump on a steep incline slope and it will continue to run as the fuel and oil are mixed, lubricating internal parts.

- There are fewer moving parts inside.

- These engines are less expensive because of their simple design.

Negatives

- These engines are noisy (high decibels from exhaust).

- High exhaust emissions: Not all of the fuel and oil mix is burned in the combustion chamber.

- Marine two-strokes leave an oily slick in the water of unburned oil and gas from exhaust.

- These engines have lower fuel efficiency.

- These engines are more likely to fail sooner, as they run at much higher RPMs (revolutions per minute) with very little lubrication on moving parts.

■ Four-stroke engines

Positives

- Oil sump to hold engine oil: this helps to lubricate more moving parts.

- No fuel and oil to mix, resulting in fewer hassles to worry about (mixing ratios).

- Engines are less likely to fail as the RPM curves are lower and the parts are continuously lubricated with oil.

- Low oil shutdown sensors

- Lower exhaust emissions

- Great fuel efficiency

- Quiet and smooth-running

Negatives

- Heavy

- Expensive to repair

- More moving parts

- Unable to position on any angle as the oil in the sump must be in the oil pump pickup tube or it will not be lubricated. For example, if a chainsaw had a four-stroke engine, it would be difficult to keep all the moving internal parts lubricated as this piece of equipment can be used at many different angles.

Some of you will know this already, and for those who do not, welcome – you are now among the firefighters and officers who use these tools to help in life rescue and the protection of property: Murphy’s Law will strike as soon as a piece of equipment is needed, so it’s important to learn how to keep this equipment in peak shape and at operational readiness.

|

|

| The top row represents gallons and the side bar is the fuel/mix ratio. The numbers in the middle are ounces of oil to use. Chart courtesy Chris Dennis. |

We all know that gasoline is less volatile in its liquid state than it is in its vapourous state. There is a difference between winter and summer gas. Summer gas is less likely to be as volatile in the colder months than it is in the warmer months due to its blending. If you do not change the gas in your small engines to winter gas from summer gasoline, the small engines will be harder to start, as the summer gas blends do not allow vapours to be as volatile. The colder the air, the less likely it is that these gas vapours will ignite in the combustion chamber. The small engines will be difficult to start in the winter with summer gas and the engines in the summer that run winter gas will run hotter, causing premature engine wear and damage. Fuel that’s stored out of season can evaporate. It can also hurt engine performance. Winter-grade fuel uses more butane as an additive; this is due to its high RVP (Reid Vapour Pressure). RVP is the vapour pressure of gas measured at 100 F. Summer fuel may use butane, but in lower quantities. Atmospheric pressure in gasoline must have an RVP below 14.7 psi. If a fuel has an RVP greater than that, excess pressure builds up in the gas tank and the fuel could boil and evaporate. Winter-grade and summer-grade fuels should have different RVPs to protect against this.

The additives in gasoline today may also cause another issue in small engines: The viscosity of the fuel begins to break down so its ignition point decreases, making it harder to start. Once started, the engine will not run at its full potential, causing early spark plug failure. We add gasoline fuel stabilizer to fresh fuel only, to help keep the gasoline in a better state. Adding stabilizer to already bad gas will not help as the damage is already done. Stabilizer allows the gasoline to stay together longer; however, the ignition point of the vapours still depletes. Change the gas outright.

|

|

| Photo 2: This is an internal combustion engine, with more moving parts, that does not require fuel and oil to be premixed in the gas tank. Photo by Chris Dennis |

I did my own study over two months on summer gas in a glass jar. I filled the jar half full of gasoline without stabilizer and let it sit on a bench. Over the two months, I watched the gas separate. There was actually a thick film on the bottom, and the yellow liquid above it is a product of gasoline. I am no chemist, but I can tell you from expierence that an engine using this gas wiill not start and, if left to sit in an engine, this gas will turn to a hard substance that will require dismantling the fuel system of the engine to clean it out.

Even the small rubber fuel lines on these engines can become hard and brittle if old fuel is left for long periods of time. Here’s a rule of thumb for changing the gas: When the clocks are turned an hour ahead in the spring, change the gasoline on your small engines, just as we change the batteries in smoke alarms. In the fall when the clocks are turned back and again the batteries in the smoke alarms need to be changed, replace the gasoline in the small engine. A little extra time and money now will save a lot of down time and money later.

■ Small engine equipment checks

I will not go into detail about how to inspect all the parts of small engine equipment but I want to stress the importance of ensuring that the equipment is being checked properly. When the engine is started and run up during truck checks, don’t immediately shut it off. You might as well have rolled in the snow, jumped in a hot tub for a few moments, then gone back into the snow and stayed there without any time to warm up. Engines rarely get to warm up, so in time, they slow down and break. Firefighters responsible for the equipment will start and warm up the tools, then allow for cool down. The engine parts that have been superheated will quickly expand, and if they are not left to slowly cool down, internal damage will occur, resulting in a breakdown. In the long run, this, too, will save on untimely repairs.

Care and maintenance are a large part of keeping the equipment we have in first-class shape. Take the time to incorporate these practices into your inspection routine and the result will be longer lasting

small engines.

Chris Dennis is the chief mechanical officer for Vaughan Fire & Rescue Service in Ontario.

Print this page