Equipment

Truck Tech: May 2018

There is a part of every vehicle we depend on the most, but it’s one that we take for granted. We start a vehicle — be it our everyday driver or a multimillion dollar fire truck — put it in gear and just expect that when we push the brake pedal with our foot that the vehicle is going to come to a full stop. Let’s put this in perspective in the fire station.

April 19, 2018

By Chris Dennis

The rigs sit at the ready backed into the station. The alarm sounds. The crews move to the trucks and proceed to the emergency. It’s at this point that everyone in that truck is focused on game day and what they have been trained to do. The accelerator pedal is pushed to the floor. Lights, siren and airhorns are all in check. Seat belts are on and firefighters are ready. At the first intersection, the light turns red upon approach and the intersection is busy. The accelerator pedal is released and the brake pedal is applied. It’s at this time we assume that all the functions of the brake pedal are working and that this 40,000 lbs plus piece of rolling thunder is going to stop. Thankfully, a good job on the truck checks was performed. The truck stops without concern. The crews carry on, perform the job at hand and return to the station. The apparatus is parked back in the station. All equipment used is taken off the truck, checked, cleaned or replenished and deemed sound for the next time. Post trip circle check of the rig is done. Appropriate inspection forms are filled out and submitted to the captain for truck records as all good for the next call.

All sound good? Here is my concern. Every woman or man who has a valid operator’s licence to operate and drive a fire truck with air brakes in Canada must be able to do a brake checks in accordance with the Ministry of Transportation (MTO). This means that brakes need to be re-checked during regular station routine truck checks and post trip truck checks as per the standard in your province for a Z air brake endorsement. This procedure should be part of your post truck equipment and truck circle check. How will you know if something has failed unless you take the time to actually look, mark and measure the brake stroke and observe the brakes functioning unless you get under the truck to check. However, the standard can be met with resistance.

The first push back is, “I am not a licensed mechanic so I don’t know what I am looking at or for.” The second push back is, “the truck is too low to get right under it to inspect the brakes.” Remember, as a qualified driver engineer, the firefighter must be able to perform these checks no matter what. If they hold a valid air brake endorsement they must be able to back it up. By simply by holding an air brake certification alongside the driver’s license accreditation, the driver must be able to mark and measure, perform behind the steering wheel air tests, listen for audible air leaks and know the names of all the air brake parts associated with the Z air brake endorsement they hold. I realize the driver already has a lot on his or her plate as a firefighter. They have been selected to perform this dubious task as either a duty or job function when hired or promoted to this position. The responsibility of the driver is important to crew safety, citizen safety and the ability to respond to the call to assist those already in a bad state or situation. The idea is to “respond to the emergency, don’t become the emergency”.

Here are some inspection suggestions if you do not have them already in place, as welI as some technical information to explain air brake systems versus hydraulic brake systems.

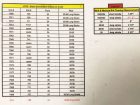

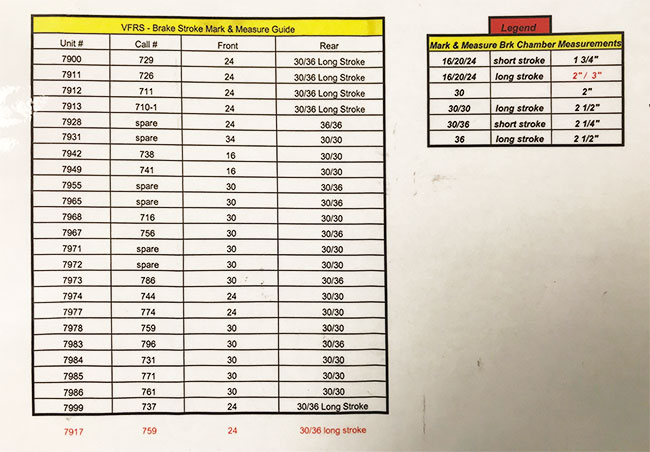

First things first. Make the truck safe for inspection. Chock the wheels. Having a form made up and laminated (Photo 1) referencing the brake chamber size as well as long stroke or short stroke designation with appropriate brake stroke measurements in every single truck. Whether it’s in a binder or on the vehicles tablet or MDT, it should be in a place that everyone can access so that the driver knows what the correct brake stroke should be for that rig. This is beneficial for a few reasons. The driver who is dedicated engineer will know their truck and what brake chambers sizes are on their truck for measurement purposes. If the engineer or driver is moved to another station or called in on overtime to drive a rig they are not familiar with they automatically will familiarize themselves with the truck and its equipment and functions. The driver will perform a truck check and when it comes to doing brake checks will need to know the brake chamber size and if it is a long stroke or short stroke chamber. The purpose of this is to determine the brake stroke measurement. If this form is in the truck, it makes for a quick reference guide without looking for the info on the brake chamber (Photo 2). If at any time the rig is subject to a roadside MTO or DOT inspection, the official will ask the driver if they did truck checks. If so, they may ask the driver to describe their brake stroke measurements. Once the driver describes the process, the official may ask how they know the correct stroke. They can then refer to the form in the truck that correlates to the unit number of the truck they are in. For example, truck # 7973, call number 786 steer axle are 30 chambers rears and 30/36 short stroke chambers. This means the front measurement on steer is two inches and the rears 30/36 is 2 ¼ inch. This is more than acceptable and a quick reference guide. The second means to check brake stroke is to install brake stroke indicators, brake safes or cheaters as they are commonly known (Photo 3). This process of installation requires a certified licensed mechanic. They can be purchased from any truck part supply store and are not specific to the manufacturer (universal). When ordering, you will need to know the size and stroke of chamber you are installing it on. Once installed to the correct measurement, the process to perform brake stroke inspection is visual only. The need for a ruler or measuring tool is not needed. The math is done. The process to perform brake stroke inspection is initiated. The inspecting person under the truck only has to see that when the brake is applied, the moving pointer that is installed on the clevis pin connecting the brake chamber push rod to the slack adjuster is between the two fixed pointers attached to the brake chamber mounting bolts. If the moving pointer is between the two fixed pointers at rest, then again applied, the brakes are in adjustment (Picture 4). This does not exclude the driver from knowing how to mark and measure. It’s just made the inspection process quicker and easier. The inspector does not have to even go under the truck completely to see the brake being applied. They will see where the pointer stops and know whether brakes are in safe adjustment.

Its important that when checking brake stroke that the air pressure be at 100 psi on the gauge on the dash or six to seven bar/kpa. The reason for this is min air pressure before low air warning comes on. The person you have selected to assist by applying the brake pedal should remember the park brake must be released before the brake stroke test be performed. The amount of brake pedal pressure should be equivalent to the amount of holding pressure applied to hold the truck on a moderate hill or at a traffic light. Do not stand on the brake pedal. Incorrect measurements will be noted. The internet is a wonderful tool for YouTube videos as well as provincial web sites referencing air brake testing, for example www.transportation.alberta.ca/1877.htm.

A commercial vehicle equipped with hydraulic brakes in the fire service also needs to be inspected. For those of us that have been around for a while, there was a time (perhaps 30 years ago) when believe it or not fire trucks (even custom-built fire trucks) only came with gasoline engines and hydraulic brakes. That was not that long ago. Now we have 1-ton and 5-ton emergency response vehicles fit with lights and sirens with gas engines and hydraulic brakes. The process for brake inspections with these vehicles is different. The post trip check still needs to be done. This can be done on the return trip back to station from the call you just responded to with hard acceleration and hard braking. If the unit responded without issue then on the way back to station, brakes can be checked. Follow these few pointers on the road then back in station.

- Can you smell burnt brake material?

- Does the vehicle pull to the left or to the right when brake pedal is applied softly then hard?

- Do you notice any noises when the brakes are applied that where not there before?

- Does the vehicle brake pedal feel like it is pulsing up and down under your foot when the brakes are applied when coming to a full stop?

- When pulling away from a full stop does the truck feel like it being held back as if brakes not releasing?

- Back in station check each wheel end for excessive heat radiating from the wheel or rim area. Use of a TIC can be used as well.

- Once parked, is there any smoke rising from a wheel?

- Check all brake lights. Make sure they come on and when the pedal is released the lights turn off. If they stay on, there is a possible hydraulic issue or a switch. The brakes may not have released completely.

- Open the hood and check brake fluid level, colour, heat and for moisture

- Are there any signs of brake fluid leaking onto the floor?

- Take note if the brake pedal has faded when being applied, there is a serious issue.

The above listed items are all out-of-service criteria if evident.

Whether you are full-time, composite, or all volunteer department, truck checks should be an internal requirement. If your department solely depends on an outside entity performing brakes checks then the odds of failure are apparent from one outing to the next. An inspection also has to be based on how often a rig rolls down the road for anything.

If your department at this time does not perform in depth brake checks, take some time to put a program together for your department. You can draw from the MTO air brake handbook for your province as a start. It will prompt the drivers to see more of the truck as well as help in preventive maintenance. The more they see and touch, the more they get to know what is correct and what is not. Early detection means less chance of failure. The likely hood of a catastrophic failure will be reduced, improving safety and repair costs. Think of it this way: Every time you use the brakes, they are one step closer to being worn out.

Rubber side down my friends.

Chris Dennis is the chief mechanical officer for Vaughan Fire & Rescue Service in Ontario. He can be reached at Chris.Dennis@vaughan.ca.

Print this page