Features

Training

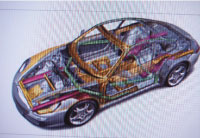

High-tech transportation: New developments make vehicles stronger and challenge rescue personnel

|

| New materials used by automobile manufacturers make it more difficult for firefighters to know which tools work best for extrication. PHOTOS COURTESY PETE METHNER |

New materials

During the North American International Auto Show in Detroit in January, I was blown away by the advancements of the manufacturers. From multi-functional air-bag systems to even higher strength steel, which forms the framework of the safety cages of today’s new cars, vehicles are becoming lighter on the outside but stronger on the inside.

These new materials make up different parts of each vehicle’s inner structure. They also enhance the overall safety of the vehicle. This means rescuers must learn exactly what materials are being used and for what purposes. Rescuers are already familiar with mild conventional steel, high-strength, low-alloy (HSLA) steel, boron and even micro alloy, which are widely used today. The use of micro alloy and boron steels for side-impact and roll-over protection is becoming an industry standard. Manufacturers have also introduced extra high-strength steel, which will create further challenges during motor-vehicle rescue. Rescuers need to determine which heavy hydraulic rescue tools will be able to cut these new materials and what, if any, shortcuts can be taken to meet these challenges.

One example of this new construction is the Volvo S40, which uses different grades of steel in different areas. On the S40, the front body is divided into several zones and each zone has a different deformation process. On this model, the passenger compartment is designed to remain intact in most collisions. This zonal system enables collision forces to be absorbed in a highly effective manner. The co-operation among the different steel grades is also a vital aspect of protection in other types of collisions.

Airbags

Over the last several years there have been many concerns about airbags. I remember back in 1997, in Vancouver, listening to Bill Davies of General Motors educate a group of rescuers about airbags and listen to the concerns for rescue personnel. At the time, rescuers were worried about their safety as well as that of the patient. Hearing about driver- and passenger-side airbags was a big deal. Today, we are concerned about side-impact protection, head-impact protection and even knee bags, which deploy from the knee bolster area.

|

| Firefighters in Niagara Falls, Ont., perform a total roof removal to extricate a driver from a vehicle after it collided with a transport truck. |

|

Rescuers must also be concerned with the possibility of cutting the compressed air cylinders that deploys the head-impact protection system. Cylinders can be located in different spots, depending on the vehicle, and must not be cut while under pressure. The head-impact protection system cylinder can have as much as 3,500 psi of pressure. If the HIPS has deployed, rescuers can cut the cylinder out of the way to perform a total roof removal. If the cylinder is cut while under pressure, it can explode and send small metal shrapnel through the interior of the vehicle, causing further injury to the patient and injuring the rescuer.

If the head-protection system hasn’t deployed during the collision and a total roof removal is necessary, rescuers should strip the trim to locate the compressed-air cylinders These gas cylinders may be located in the lower mid section of the C pillar and in the mid section of the A pillar, between the dash line and the roofline, or in both locations. Rescuers need to take a few additional seconds to locate and isolate these cylinders before removing or cutting any material. Both air cylinders can also be located along the rear of the roofline in the centre area, as is typical for the Audi A3.

Two years ago, Mark Uttley from Windsor Fire & Rescue and I spoke to the Original Equipment Manufacturers (OEMs) about airbag safety and firefighter safety. One of our key messages was the time it takes to rescue a patient from a vehicle, whether they have non-life threatening or life-threatening injuries. The manufacturers were impressed by the graphic presentation but they had no idea of the importance of imparting technical information about their vehicles to firefighters until we presented our perspective.

This was another step toward the auto industry taking rescuers more seriously when we call for information. It also gave us an opportunity to view some of the manufacturers’ proposed changes, including relocation of airbag deployments and relocation of compressed cylinders. One change under consideration was locating the inflatable cylinders in the roof line just above the front and rear windshield and removing them from the A and C pillars. This would reduce the time it takes to perform a total roof removal because rescuers wouldn’t have to strip the interior trim first.

In 2006 General Motors of Canada started using the Delphi Dual-Depth Passenger Airbag system, which provides tailored volume and inflation levels to match the needs of the occupant in a specific crash situation. The Delphi Dual-depth Airbag can deploy in a small or large size based on seat position, seatbelt use and crash severity. By tailoring volume and inflation rate, dual-depth airbags help to protect the passenger. These airbags were first available on the 2006 Buick Lucerne and 2006 Cadillac DTS and the 2006/07 Cadillac Escalade. The bag’s inflation energy is also adjusted at two different pressures according to crash severity. This represents the next generation of airbag technology because of the potential to help restrain a front-seat passenger in a greater variety of seating and crash situations. A conventional dual-stage airbag inflates to a single shape with different pressures. The dual-depth airbag is fully compatible with existing restraint electronics products and no architecture changes are required.

Auto manufacturers have been preaching since the late 1990s that rescuers should disconnect the negative side of the battery and then the positive side to ensure that undeployed airbags don’t accidentally go off during a rescue. Now, with advancements to electrical systems, simply removing the key from the ignition ensures that the airbags will not deploy. Rescuers were also taught to be wary of a back feed from auxiliary power locations such as cigarette lighters or cell phone plugs. Vehicle electrical systems are now designed to prevent this type of power back feed.

|

| Top: A manufacturer’s computer-generated model uses colour codes to show the numbers of different types of steel used in new cars. Bottom: The SMART Car is one of the safest cars on the road, with more safety features than some full-size vehicles. The SMART Car’s Tridion Safety Cell distributes impact throughout the entire frame of the vehicle. |

|

Rollovers

The myriad crash sensors on any vehicle are complemented by crash-avoidance systems such as standard StabiliTrak with rollover mitigation. The electronically controlled system continuously measures the side angle of the vehicle and, if a rollover appears imminent, it can deploy the side-curtain airbags before the crash occurs. The 360 degrees of detection capability allows the electronically controlled safety systems to deploy in a greater variety of situations. This is a safety feature that General Motors should brag about. It’s fantastic as far as safety goes and with the StabiliTrak there should be fewer rollover situations. A few years ago, Land Rover released a model with a dual gas cylinder head-protection system with the cylinders in the lower portion of the dash and across the top of the roof between the C and D pillars. These systems inflate a fairly large head-protection airbag and will keep it inflated long enough for a possible second or third rollover. Rescuers need to be mindful of the cylinder location on the Land Rover and avoid using spreaders or rams on the dash portion of the vehicle.

Glass

Another change in vehicle technology is the use of stronger, laminated glass. Mercedes Benz has used this technology in the S-class and SL-class for the past few years. This glass acts as a theft deterrent but also increases safety because it’s stronger. Rescuers can determine if this type of glass is in place by looking for the words Laminate or Sekurit on the side-door window. Also, the edge of the glass is slightly thicker because the two panes are offset just a bit. When trying to access this type of glass you may need to use a Glassmaster tool if a centre punch doesn’t work.

Seating

Ford and Daimler-Chrysler were the first two North American companies to introduce the hide-and-go or stow-and-go seating, which allows seats to be folded down into the floor. This is a great option when rescuers have to get to the driver and front passenger but can’t get to them from the front of the vehicle.

SMART Cars

I have had more safety questions about the Mercedes Benz SMART Car than any other vehicle I have had the opportunity to talk about. The SMART Car was designed to be one of the safest cars on the road and it has more safety features than some full-size vehicles. The safety comes from the Tridion Safety Cell, a reinforced cell that distributes impact throughout the entire frame of the vehicle. The cell is designed with three layers of metal and is reinforced at strategically important points with high-strength steel to keep the occupants safe in a crash.

When the SMART Car is involved in a collision, the longitudinal and transverse triple reinforced cross members activate the crumple zones of the other vehicle. The black underbody framework is made to travel underneath the vehicle and break away upon rear collision. This prevents the framework material from intruding to the interior of the vehicle.

In the interior of the door frame there are two side-impact beams that run from the hinge to the lock mechanism as well as to the door-latch mechanism. This upper door frame doubles as side-impact protection. It is located higher than the normal height of a door. This feature evenly divides and distributes the side impact between both A and B pillars.

With all this information from the auto manufacturers, take a look at your extrication equipment and ask whether you have the tools and the training to safely and proficiently deal with these new vehicles. Be well prepared as well as properly trained.

In the meantime, stay safe.

Pete Methner is a firefighter in Niagara Falls, past education chairman for the Transportation Emergency Rescue Committee for Canada and the president of ON SCENE Rescue Training. He has competed both regionally and internationally and has taught firefighters from around the world. Contact Pete at autoexed@cogeco.ca

April 8, 2008

By Pete Methner

Print this page

Advertisement

Stories continue below

Related