Equipment

Hot topics

Truck Tech: Let’s talk tires

August 30, 2021

By Chris Dennis

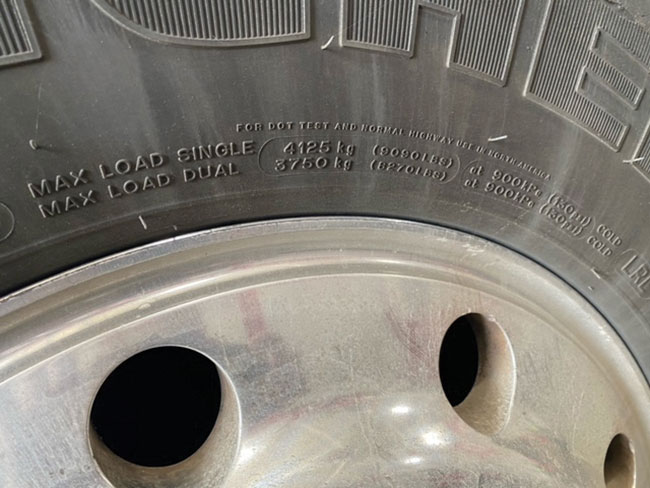

Here is the location of tire inflation and load information.

PHOTO CREDIT: CHRIS DENNIS

Here is the location of tire inflation and load information.

PHOTO CREDIT: CHRIS DENNIS Let’s talk tires. Wait don’t go away! I have often bypassed tire seminars as a technician only to find myself learning something every time I do go.

What is a tire, really? The quick answer is that it’s the round black thing full of air mounted on a rim that allows the vehicle to roll down the road with ease. But there’s a lot more to tires than allowing the vehicle to roll easily down the street.

Cavemen may have invented the round wheel, but in 1888 it was John Boyd Dunlop invented a pneumatic tire (though, according to the National Museums of Scotland, he was unaware that Robert Thomson had already patented a design for a pneumatic tyre in 1846). Dunlop’s tire was installed on a bicycle. Before Dunlop and Thomson’s inventions, there were tires of wood, wood with steel wrapped around, as well as leather. Dunlop’s invention was designed to help his son who suffered from headaches while riding his bicycle on rough roads. This new tire would help to cushion the blows of rocks and pot holes. Paved roads were not in the mix yet. From this era came patent after patent. What became of it this is the tires we drive on today.

Whether it’s tires from way back or tires of today, they all wear out. The difference today is the science behind compounds, tread design, side wall strength, load and speed ratings and air pressure that all come into effect. The size of a tire can also affect the total overall weight the vehicle is able to carry.

Now, let’s talk fire trucks. The trucks of yesteryear were horse drawn pumper units with steel wrapped wooden wheels. The horse pulling the cart also had “tires”, better known as shoes. These were also made of steel. Regular inspection of wagon wheels as well as horseshoes had to be done to keep the wagon on the road as well as the horse healthy and able to work. The tires on the rigs are the same.

Vaughan Fire and Rescue Services (VFRS) does all its own in-house driver training. During this training, the newest drivers are given direction on a full circle check. The tires are not overlooked. Starting at the tread, the area that contacts the road, we look for things like irregular tread wear. Tread blocks or tread shape that are not the same, cuts, snags, bulges, cupping, feathering, or foreign material stuck in the tire should all be noted (could be a nail, screw, glass, or a piece of steel). Once the visual is done, run a gloved hand over the entire tread starting at twelve-o-clock and moving down to where the tire makes contact. Do the same thing in the opposite direction. Feel for irregularities such as a separation or tire bulge. Careful, if you missed a sharp piece stuck in the tire, your hand may find it — hence a gloved hand. Move slowly down the tread face. Once this inspection is complete then look at the side wall. Starting at the tread, work down to rim bead area, this is where the tire meets the rim. Looking for bulges, deep cuts (long or short), and if tire cording is evident the tire is dangerous. You may find a long line that goes concave on side wall from tread section to bead area of rim. To find one of these lines on a side wall is common on a name brand tire. Multiple concaves with indents are common on less expensive tire brands. This is not a worry because this is actually where the tire side wall was joined. It’s heated and then when it cools it shrinks, sucking inward. This is actually a very strong part of the tire. There are more of these joins on less expensive brands of tires. My rule of thumb is two spaced out is okay, more than that or too close is not acceptable. If you find a join moving outward, that’s not a good thing. Take the tire out of service. A side wall bulge is easy to spot when it starts to show itself. How does a side wall bulge happen? Well, in my experience, the manufacturer will rarely say it’s the tire at fault so don’t hold your breath for warranty based on manufacturer’s defect. Circle the area, tag it out of service, and call a tire technician. This bulge can be caused by the low tire pressure. Driving on the road with low tire pressure causes poor handling, poor braking, poor performance and early tire wear. The outside shoulders of the tire are carrying the load so the middle of the tread sits somewhat concave. The side wall is now also exposed to more of the road surface. The side wall was designed to carry a vertical rotating mass while the tread was designed to handle the road conditions. Thicker rubber and multiple layers of product in the tread area of tire contact to the road. If under inflated, the sidewall where it meets the tread now starts to wear on the pavement. This puts undo stress on the side wall. Hit a rock, drive through a pot hole, drive over a curb, scuff or pinch the tire side wall on a curb and the side wall is now being subject to things it was not designed to do. The rim on the inside of the tire starts to cut into the inner side wall of the tire. As layers of rubber start to get shaved away inside, the rubber becomes thinner while the outside of the side wall wears away against the road. Once a few internal layers are shaved away, air can now get in between the layers of rubber inside and will show as a bulge on the outside. If you hit a pothole low on air pressure just hard enough, the side wall meets the bead of the rim and damages the tire internally, creating bulges. This is also known as an impact break. Have you ever had a flat tire and noticed a very black line running total circumference of the tire? That is the part of the tire almost worn through running on the road. Once tire is off the rim it will be full of tire shavings. This is known as run flat. Poor inflation pressures. Tire pressure monitors help as a first line of defense to slow leaks, but you should still check with a gauge regularly.

Tire identifiers

There is a lot going on with the side wall of a tire in the way of information, so much so that when you are looking for a tire pressure rating you sometimes end up going around the tire two or more times before you see it amongst all the other information.

Consider DOT information, tire size, tire pressures (single and dual), total tire loads (dual or single), as well as warranty information, tread wear indicators and direction of rotation. If you have a directional tire, Michelin in, this case, says it’s okay to run the tire in the opposite direction for the last usable amount of tread life. I know this because we had a technician notice the tire was going backwards and felt it was going to be a problem. Whether it is depends on make, model of tire and manufacturer. To get the utmost wear safely out of my directional tire, I flipped it to go the other direction for the last 25 per cent of usable tire life. The tread blocks are worn, the belting has taken on such a memory inside the tire as well as the science of building it — if anything it may just be noisy and a rough ride. There are no issues with the tire itself. I have been able to maximize tire life with crew, truck and tire safety in mind and get more for the dollar. Tire rotations often will help with tire life. Even if alignments are perfect, tight turns and backing up in tight areas all cause tire scuffing and can cause irregular tread wear. It’s cheaper to do rotations than buy new tires because a couple are scrubbed off. Over inflation of tires or under inflation will also cause poor tire wear as well as poor performance and handling. Assuming alignment is bang on, under inflation will wear the outside tread off and over inflation will wear out the middle of the tires tread. As well side walls are not able to carry total advertised load. Unlike water, air is still free. Well, most of the time. When purchasing tires, be sure gross vehicle weight rating (GVWR) is taken into consideration. The total tire inflation pressure as well as load rating of the tire will assist helping GVWR, which is the total weight of a truck full of all liquids equipment and passengers. This is most critical. Have an idea when spec-ing new tires or a new truck for that matter. There is also a marking that says DOT. NFPA 1901 tells us how to read it, and NFPA 1911 gives us the standard for the inspection, maintenance, testing and retirement of in-service automotive fire apparatus.

The entire Chapter 8 in this standard about tires is a very touchy area. If you are running your department to this standard to the best of your ability and as a guideline, great stuff. If you were to ever have an issue with your fleet, say tire related, and your tires were well within the wear limits, looked brand new, yet were over in age, this may be a challenge if it goes to court or if your driver is knowledgeable and challenges you on this. In smaller departments, especially volunteer departments, you may only respond to small amount of calls in a year. Those tires may look brand new, however it leaves you open for the “what ifs”. Tire technology today has come a long way. They advertise high mileage, smooth ride and being able to withstand the rigors of driving and weather. I am an advocate for preventative maintenance. In my own department we would never be able to make a tire last the guideline of seven years based on how many calls we run a year on front run apparatus. We do, though, have apparatus such as a field support unit (rehab), a hazmat truck and command post that would for sure would be a seven year change out. We budget for this as it is an expansive hit. Be sure you are registered with all major tire manufactures as a national account. Being a fire department, municipalities are entitled to fleet discounts on both product and labour. A tandem axle truck now with 16 ply drive tires and steers can be well north of $10,000 retail so be sure it’s in the budget.

I once sat in on a presentation done by an American lawyer name Jim Juno on investigating fire department accidents. He told one story of a used tanker truck purchased by a U.S. volunteer department. The department purchased and old U.S. military 6×6 water tanker. The truck was a late 1960s to mid 1970s vehicle. It had been outfitted by its previous owners as a fire truck and was an in-service tanker. The new department owners were very diligent about fire apparatus mechanics and safety. When the fire chief picked the vehicle up from auction, he was excited and en route to the mechanics repair shop to have it inspected for his department. What I remember is that this department was rural and drove on dirt roads. At some time during the road trip a steer tire blew out. This resulted in a crash killing the fire chief. When an investigation was done it was determined the tire failed. The pictures of the tires still on the vehicle were over 24 years old. They even looked to be the same kind of aggressive tire the military used. They also looked amazing. This is extreme but possible. So, what I am saying is use your best judgment and budget for tires. This for sure is where the rubber meets the road for safety.

Fire truck front end alignment is critical in tire wear. New independent front suspensions allow for more adjustments so tires can last longer. The firefighters driving these rigs are always our front line of mechanical defense. Prior to any trip, the trucks are inspected. Tires as well. Something as simple as a tire air valve missing a valve cap could be cause for a slow leak and tire failure. It’s happened where ice build-up against the valve stem core pushes it over and ever so slowly a tire leak. All things that can be prevented.

See that was not so bad! Stay healthy my friends and rubber side down!

Chris Dennis is the chief mechanical officer for Vaughan Fire & Rescue Service in Ontario.

He can be reached at Chris.Dennis@vaughan.ca.

Print this page

Advertisement

- Weekend rain helped Northwestern Ontario firefighters

- Arson charges laid in connection with Surrey church fire